With regards to the treatment of special industrial waste, today we increasingly deal with the disposal of end-of-life tires. In fact, unlike Italy, where the management of this special waste is regulated by the Ecopneus consortium, other countries of the world are not yet equipped and organized to treat it properly. The consequence is the presence of huge areas used to collect tyres, which increases the risk of spreading diseases, due to the massive presence of insects, and the development of fires that are difficult to extinguish.

From the very beginning of its activity, FOR REC proposes careful and effective solutions to the problem of tire recycling, to obtain secondary raw material in different grain sizes, with the simultaneous separation of steel and textile fiber.

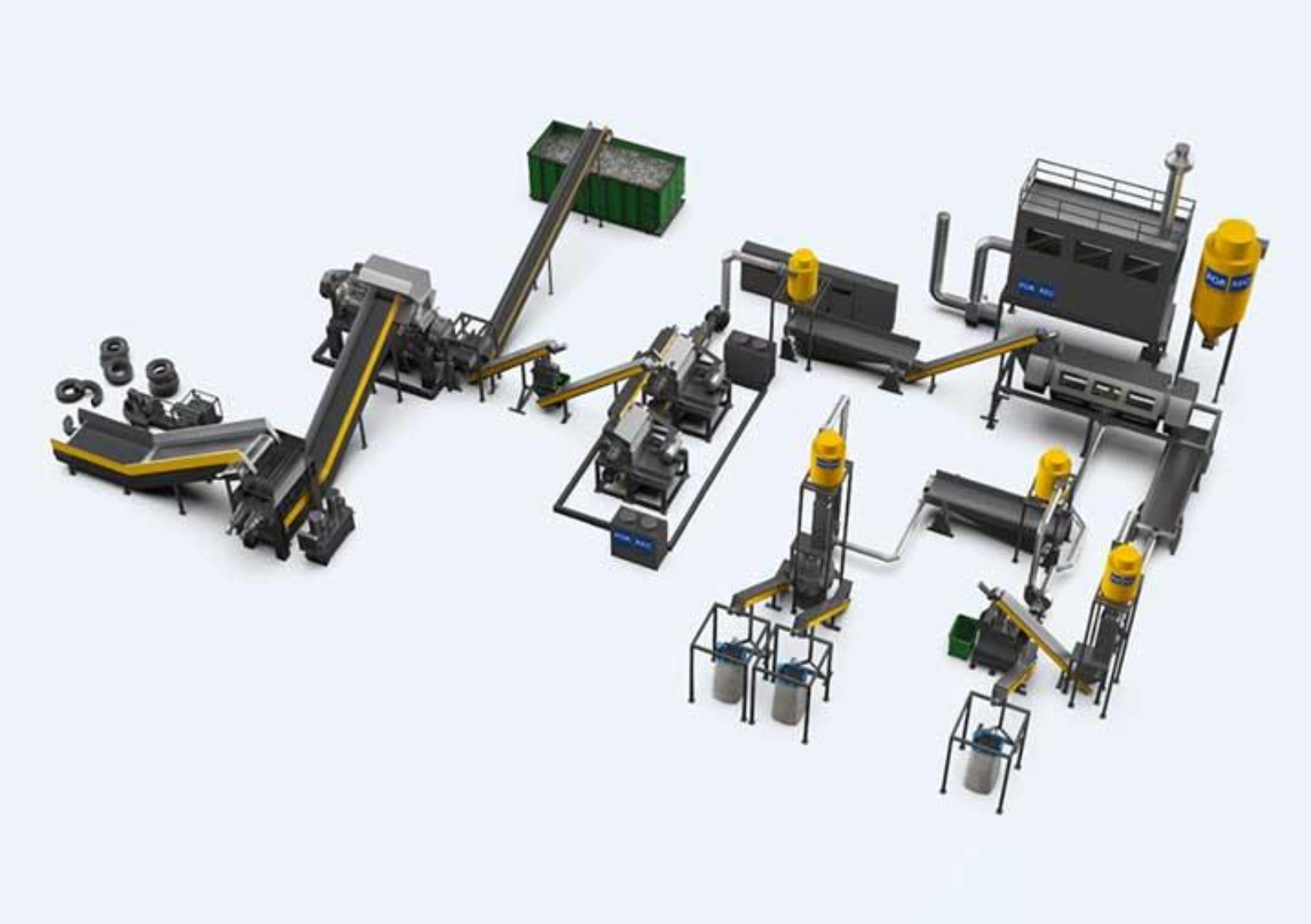

The FOR REC production cycle for tire treatment

The first phase of the process involves the extraction of the steel ring in the truck tires. Subsequently the material is shredded and reduced in size until it reaches a uniform granulometry from 0 to 4 mm, metal fraction is stored through different stages of magnetic separation.

The plant is equipped with a multi-stage cleaning system that guarantees the complete separation of the textile fiber, so as to obtain a 99% pure granulated product. Furthermore, an advanced suction system, supported by filters and fire prevention measures, allows dust control in compliance with the current regulations on emissions and safety. With these methods, it is possible to treat up to 5 ton / h of incoming material with reduced consumption and management costs.

In addition to the complete line, FOR REC has recently studied and developed the project for a primary shredder able to obtain a product with dimensions varying from 50 to 80 mm (chips). The machine is equipped with a “clean cut” of the steel wire contained in the tire rubber. The product derived from shredding with this special double shaft shredder is required in large quantities by cement factories as fuel, the so-called “tyres derived fuel”. The project was greeted with interest by the market and the first two machines will be put into operation shortly in Italy and in the United Arab Emirates respectively.

Although, despite the particularly environmental-friendly historical period, the disposal of tires is still difficult to manage, FOR REC has shown that it is possible to find concrete solutions, also thanks to continuous investment in research and innovation.